Kawa poplar timber - properties and market opportunities

Report Date: August 2023

Author: Dean Satchell, Northland Regional Council

Contact Dean: 021 2357554

Kawa poplar - thermal modification

Thermally modified Kawa poplar received back from Tunnicliffe Timber

General appearance of the thermally modified poplar

All knots checked, even small ones

Spike knot showing checking

Cupping in thermally modified Kawa poplar

Straight lines in black marker showing level of crook sometimes seen

End splits in thermally modified Kawa poplar. The extent of these was not measured before and after thermal modification

Knot checks appeared to increase from the thermal modification process

Distortion resulting from the themral modification process

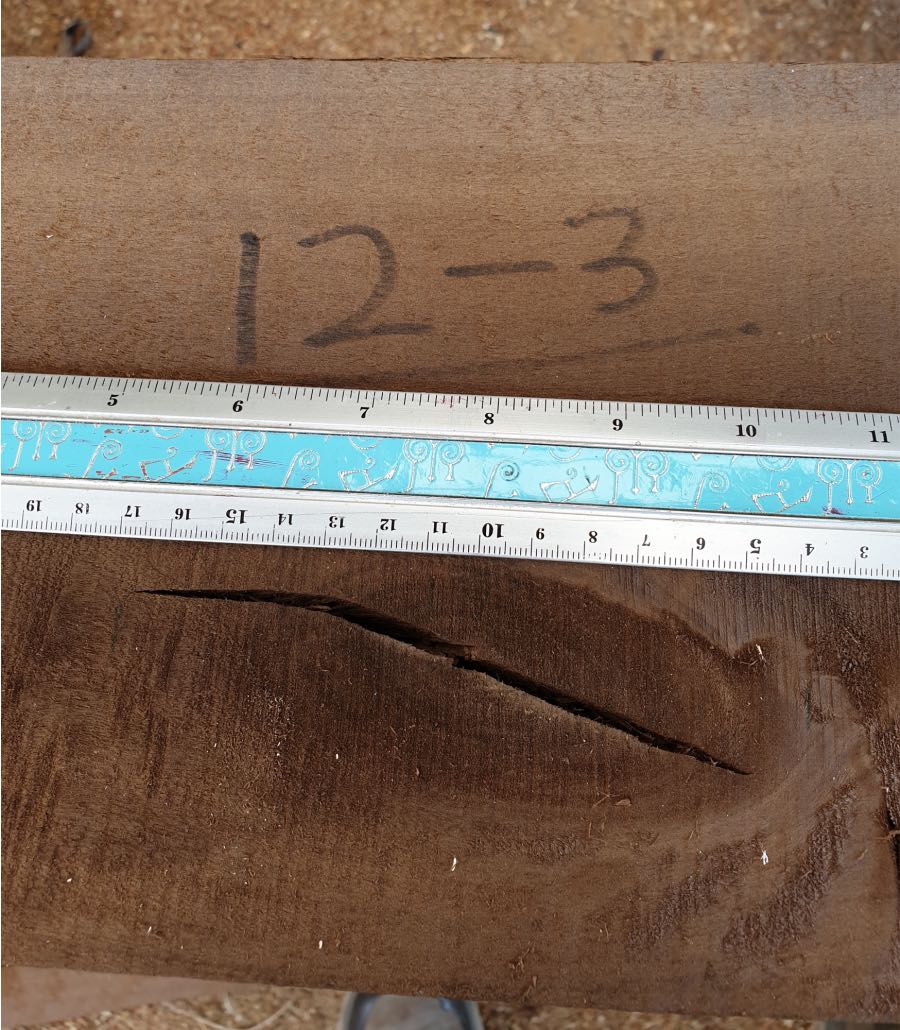

Crack in thermally modified timber. The extent

Knot checks

Knot checks

Split where the pith was included in this board

Crack showing depth

Skip caused by cupping

Skip caused by cupping and distortion around a knot

Splitting 50mm thickness timber for a bandsawn face on weatherboards

Thermally modified shiplap weatherboards

Thermally modified shiplap weatherboards

Knot check in weatherboard face

the same knot check on the other face

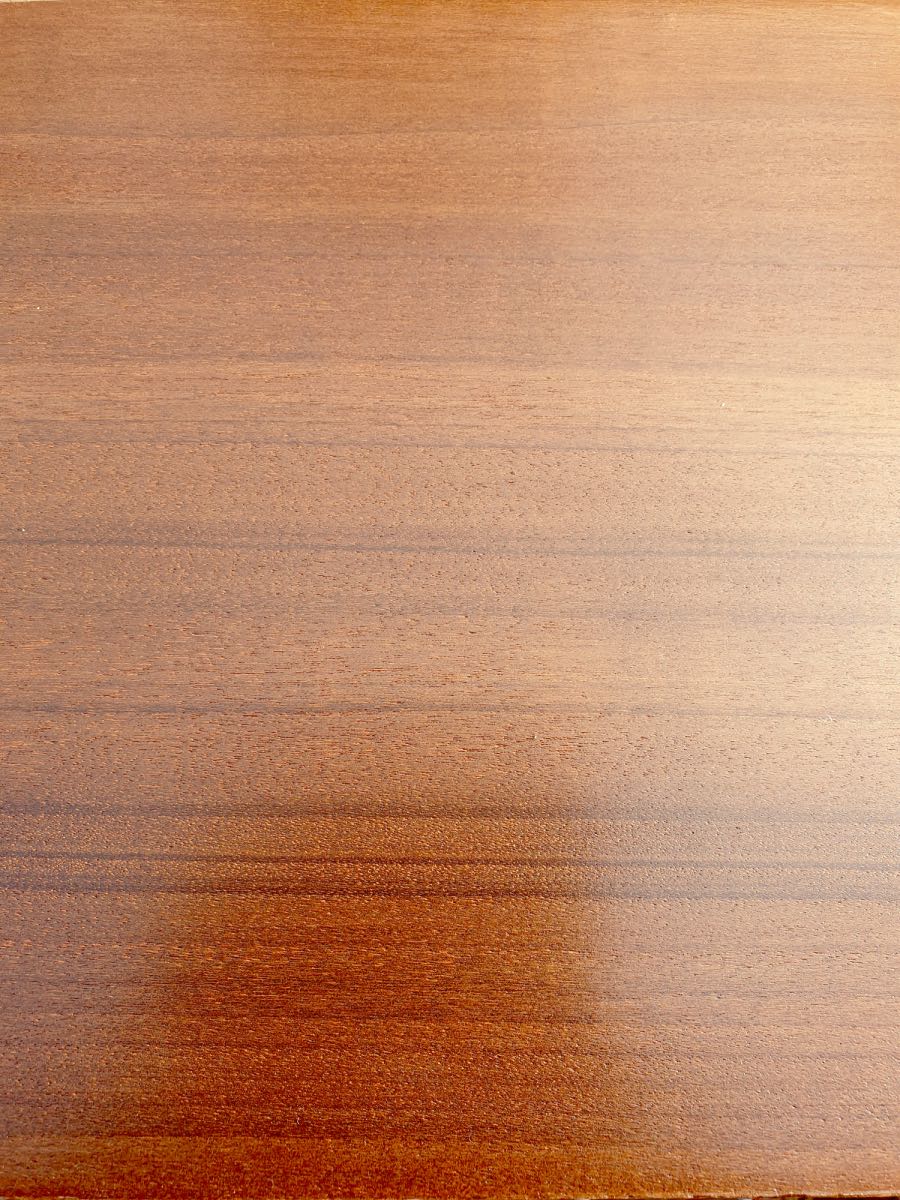

Water-based polyurethane coat on thermally modified Kawa poplar

Disclaimer: The opinions and information provided in this report have been provided in good faith and on the basis that every endeavour has been made to be accurate and not misleading and to exercise reasonable care, skill and judgement in providing such opinions and information. The Author and Specialty Timbers New Zealand will not be responsible if information is inaccurate or not up to date, nor will we be responsible if you use or rely on the information in any way.

Specialty Timbers New Zealand

Specialty Timbers New Zealand