Search technical reports

Twin bandsaw mill prototype commissioned

By Dean Satchell, February 2026.

Specialty Timbers NZ report

Executive summary

Thanks to:

- the MPI Te Uru Rakau Wood processors growth fund for supporting the development of this sawmill prototype.

- Peter Davies -Colley for his support, faith in us and his generous in-kind contributions

- Jono Sole, Sole contracting for his amazing fabrication skills and ideas

- Cole Meara, Meara Engineering for preparation of parts

Cost efficiency of a prototype twin vertical bandsaw was assessed for a range of log diameters for three tree species: poplar, eucalypt and Japanese cedar. Logs were sawed into boards and labour costs plus electricity costs were modeled per cubic metre of sawn timber according to log diameter. Results demonstrate the commercial potential of this innovative technology using a unique carriage system based on end-dogging.

Introduction

A large cost-efficiency gap exists between portable and commercial sawmills. Commercial sawmills in New Zealand almost exclusively saw radiata pine for well-established domestic and export markets, and do so in a competitive environment where costs must be low to survive. Scale is important, with larger sawmills securing greater efficiencies of scale. Portable sawmills operate exclusively at the small scale and because cost-efficiency is low, timber value must be high. They tend to cut specialty high-value species and buy logs at a low rate to ensure they operate at a profit. Portable sawmills also tend to operate in the forest where the trees are harvested, which reduces or eliminates transport costs. Buying logs at a low rate does not encourage market development for specialty timber species, because the grower will not plant a tree species unless they perceive the species to be profitable.

Operating at the small scale is necessary both because of the limited scale and disparate nature of the specialty log resource and also because the market for specialty timbers is underdeveloped. This report assesses an innovative prototype sawmill designed to maximise cost-efficiency and grade recoveries, while minimising degrade. The sawmill comprises a twin vertical bandsaw mill combined with a twin-blade edger. The objective was to build a sawmill that captures some of the cost efficiencies offered by larger scale fixed sawmills, while minimising the capital outlay. The sawmill itself is not designed to be portable, so requires a supply of delivered logs and a 3-phase power supply.

The twin bandsaws, edger, log loading bench, log turner, and board outfeed bench were purchased from China. This equipment is normally used within a linear sawmilling arrangement, whereby the twin bandsaws only make one cut on the log. To avoid the high capital costs setting up a linear sawmill line with multiple pieces of machinery, end-dogging feed carriages were devised that enabled a reciprocating wood flow (i.e. multiple pass cuts from the same machine). These were designed and built in Northland with financial assistance from MPI's Wood Processors Growth Fund.

The log infeed and outfeed was designed using CAD software with the assistance of a structural engineer, and built using a specialist fabricator and a local engineering firm. The design uses 50mm wide end-dogs at both ends of the log. The end dogs are attached to carriages that run on overhead rails, so the log passes through the twin bandsaws between the infeed and outfeed, to cut two slabs with each pass before returning for the next cut. Only one piece of equipment (the twin bandsaw) is necessary to cut the log into slabs and log rotation is not required. The resulting slabs are then edged with a twin blade edger into boards.

This "face-then-edge" cutting method offers both the ability to choose where each board is edged based on its features (for improved grade recoveries), while also mitigating crook that results from quartersawing hardwoods. The result is high grade recoveries. Because thickness variation is mitigated by sawing slabs from both sides of the log simultaneously, this sawmilling method potentially improves cost efficiency by allowing longer log lengths to be sawn.

This study quantified the required labour inputs and keys costs to capture the sawmills cost efficiency parameters.

Methods

Log diameters and volumes were measured and length of time (in seconds) was measured for both bandsawing logs of varying diameters into slabs and edging boards from those slabs. Eighty-five logs from three species of timber were milled:

- 22 poplar logs (a soft hardwood), log length 4m;

- 17 blackbutt eucalypt logs (E. pilularis, a hard hardwood), log length 4m; and

- 46 Japanese cedar logs (Cryptomeria japonica, a softwood), log length 5m.

Target sawn timber nominal widths from the hardwoods were 100mm and 150mm, and 150mm and 200mm boards from the softwoods. Nominal thickness was 25mm for slabs and 50mm for the central flitch.

We based our labour inputs on a 3-person operation, with the third person manning the edger outfeed, block stacking edged boards, stacking and removing slabwood, and forking logs into the mill. This allows the bandsaw and edger operators to focus on their respective tasks without distraction.

Cost assumptions in our model were:

- Bandsaw operator $40/hour

- Edger operator $30/hour

- Extra person $30/hour, time required = to bandsaw operator

- Sawn timber recovery: 60%

- Electricity $0.25 per kilowatt hour

Statistical analysis of regressions used Microsoft Excel.

Results

| Bandsaw time (minutes) | Edger time (minutes) | Labour cost* | Electricity cost* | |

|---|---|---|---|---|

| Poplar | 64 | 49 | $99.47 | $16.06 |

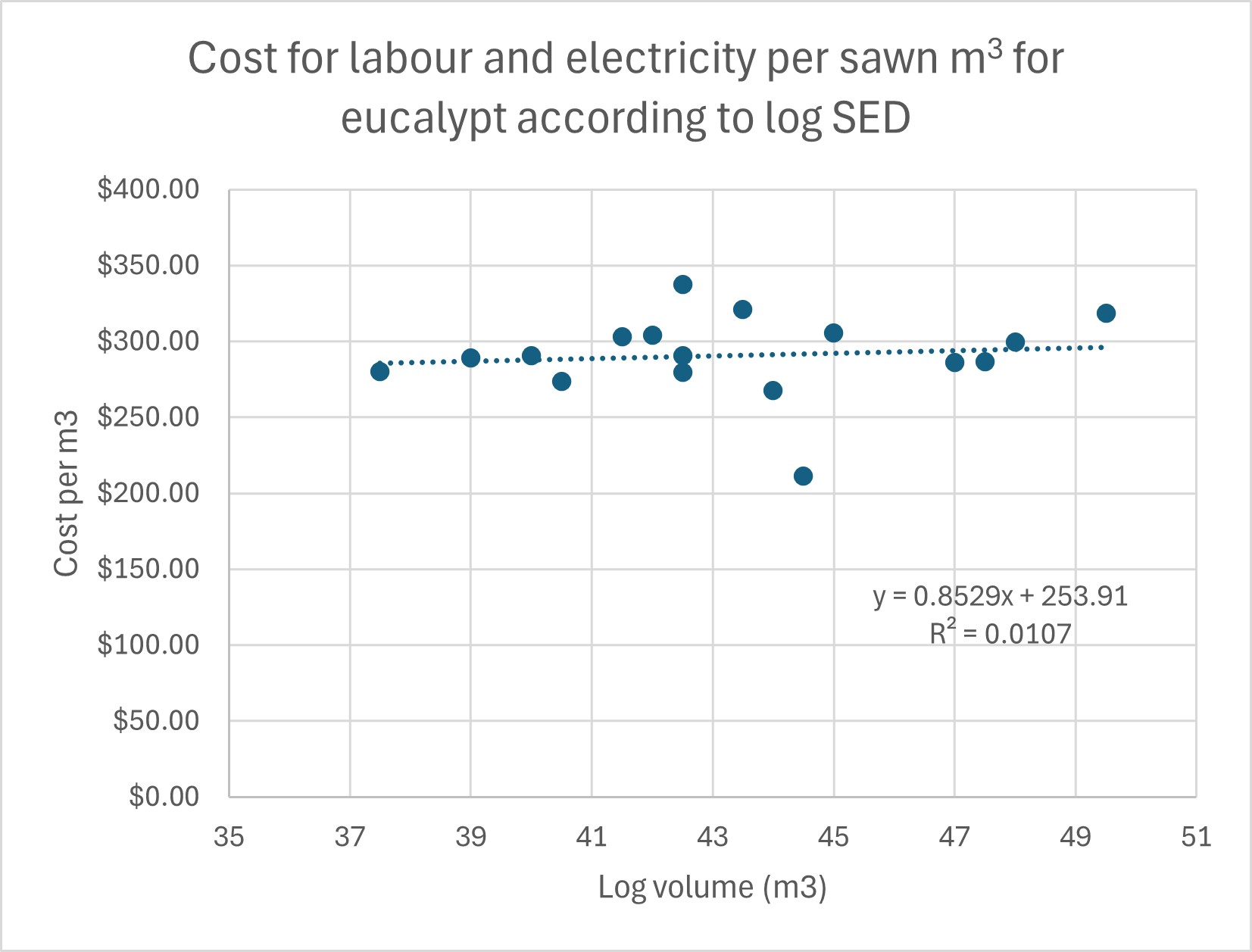

| Eucalypt | 93 | 86 | $151.35 | $23.18 |

| Japanese cedar | 49 | 42 | $78.28 | $12.31 |

*Based on a 60% recovery of sawn timber, and a 3-person operation.

Poplar

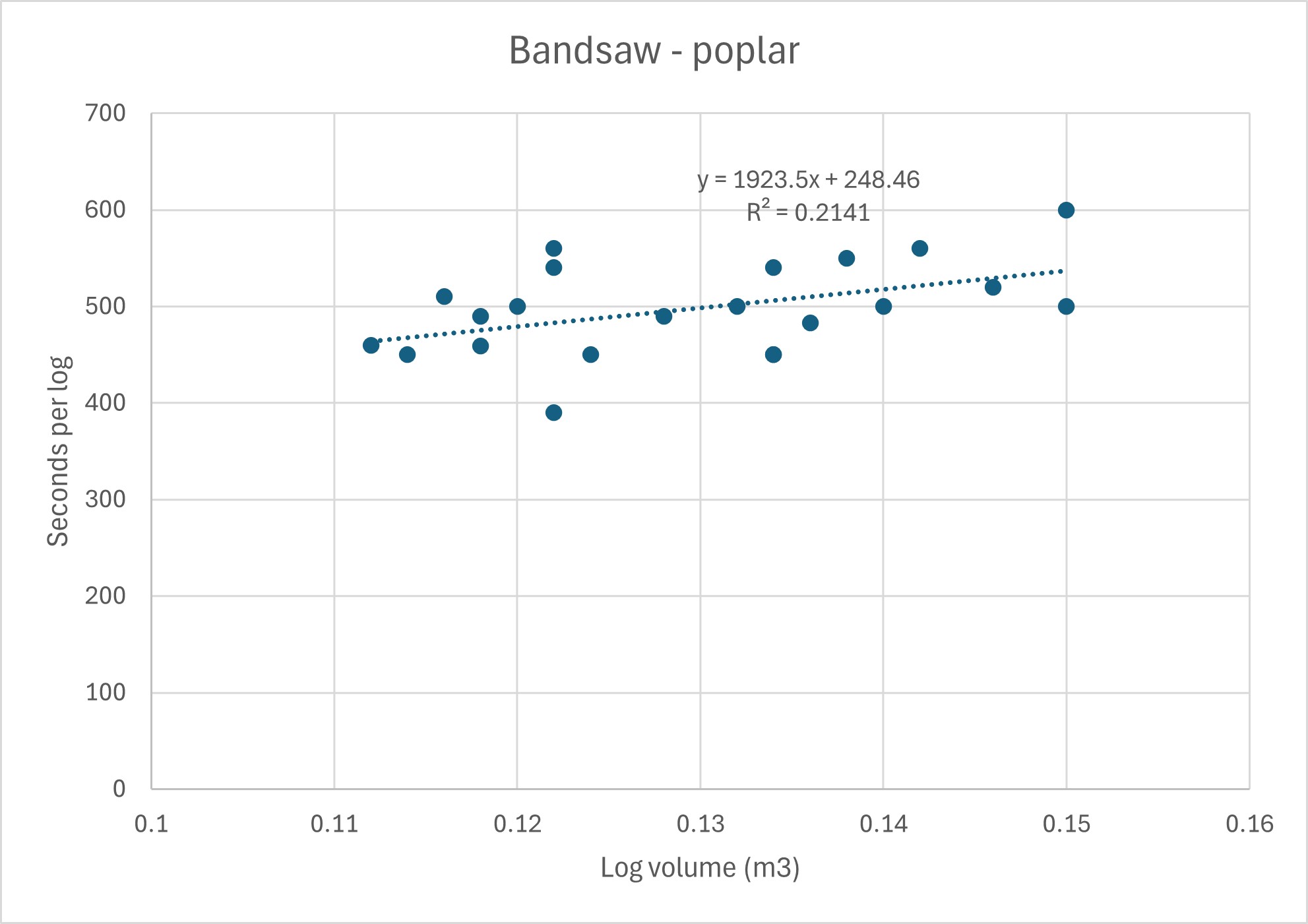

Bandsaw volume sawn vs time regression was statistically significant with a P value of 0.01.

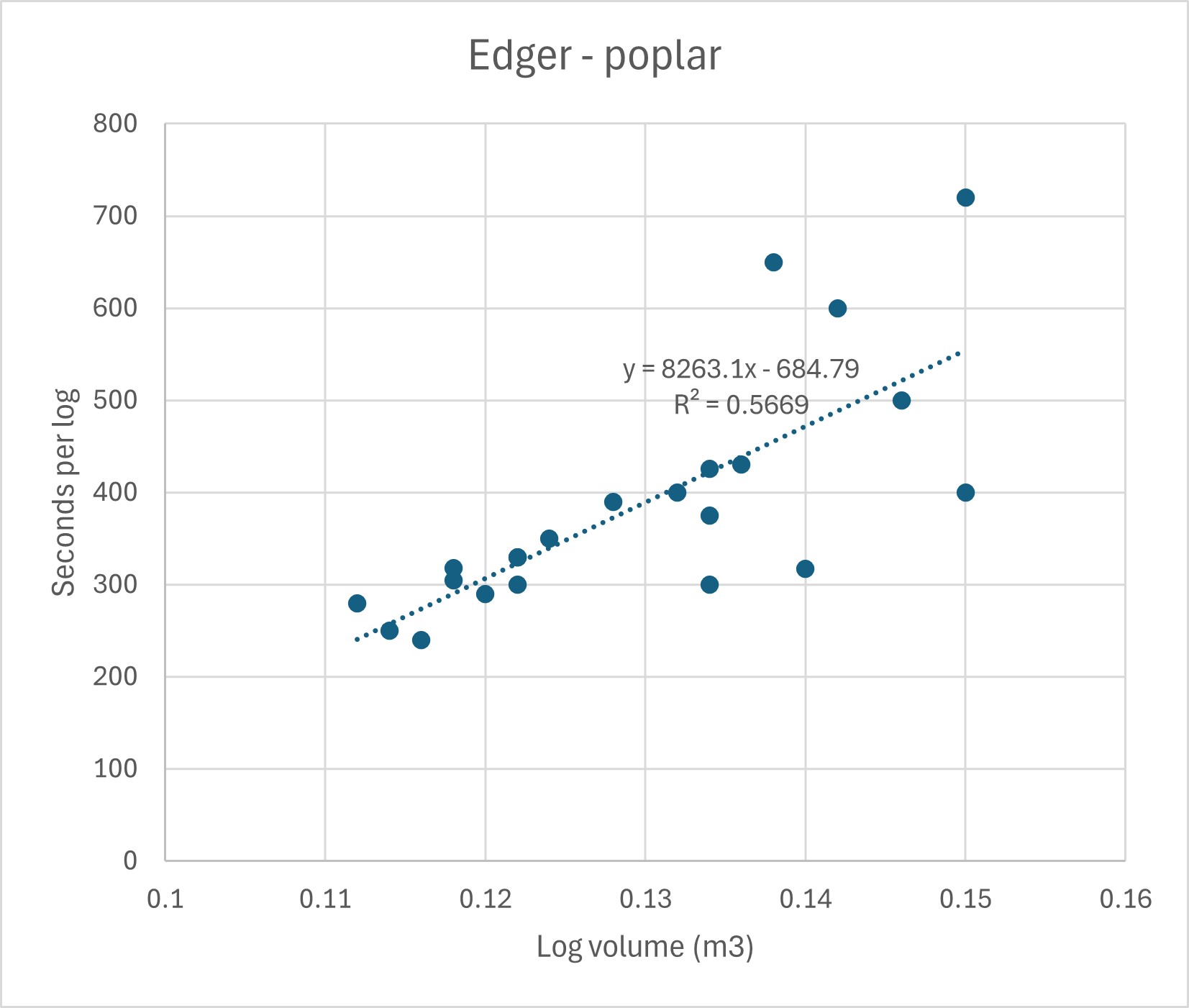

Edger volume sawn vs time regression was statistically significant with a P value of 0.0009

Eucalypt

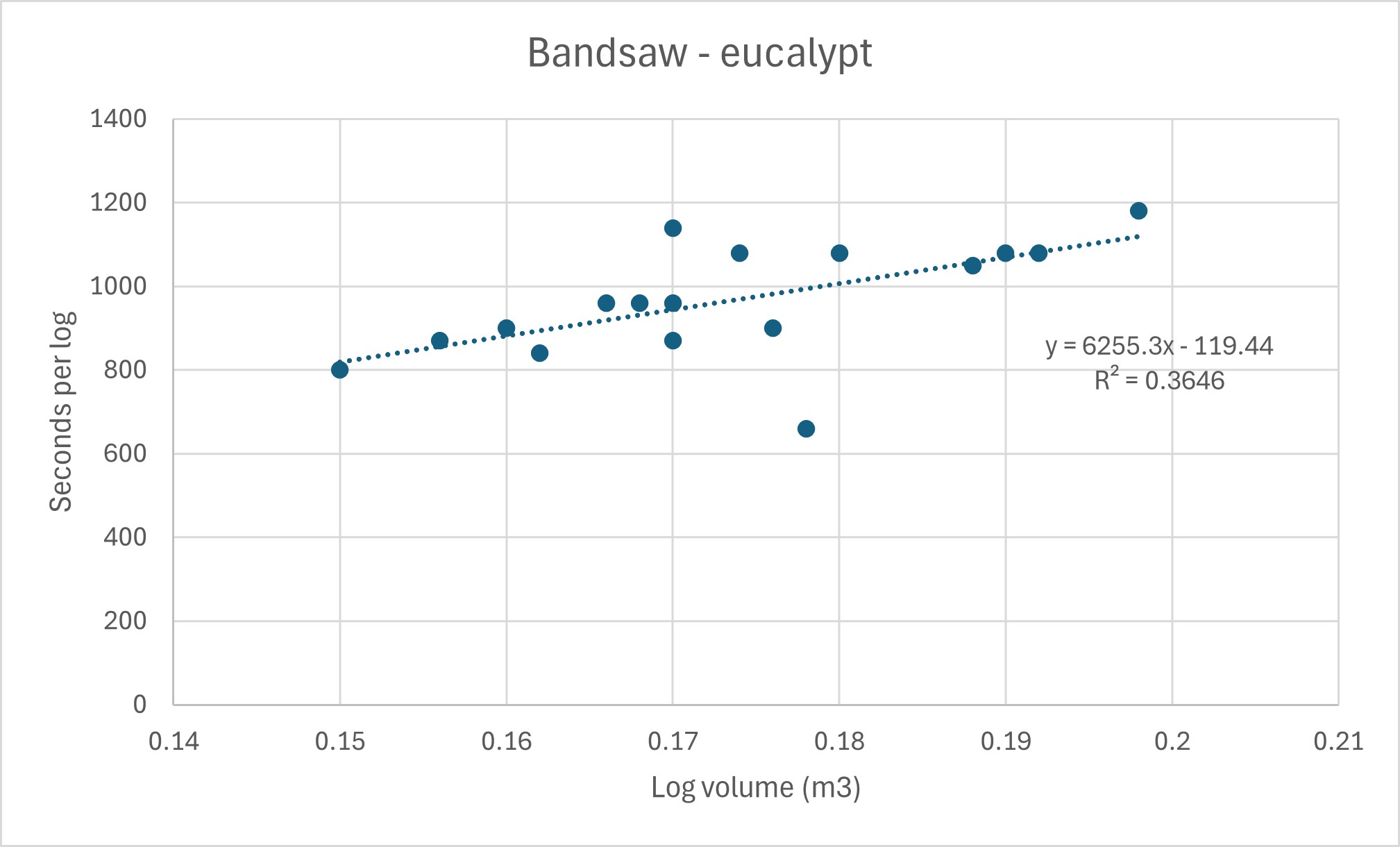

Bandsaw volume sawn vs time regression was statistically significant with a P value of 0.01

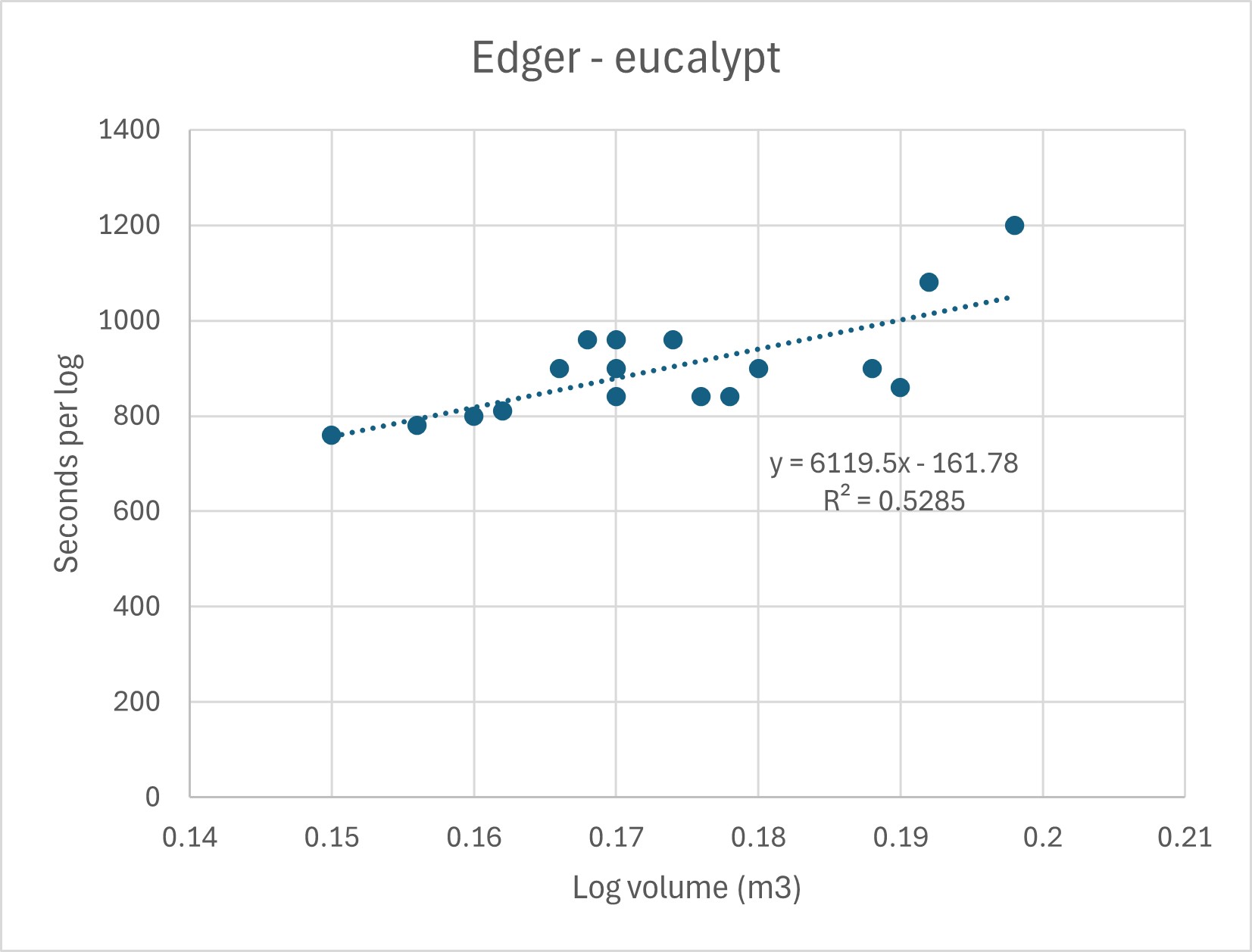

Edger volume sawn vs time regression was statistically significant with a P value of 0.0009

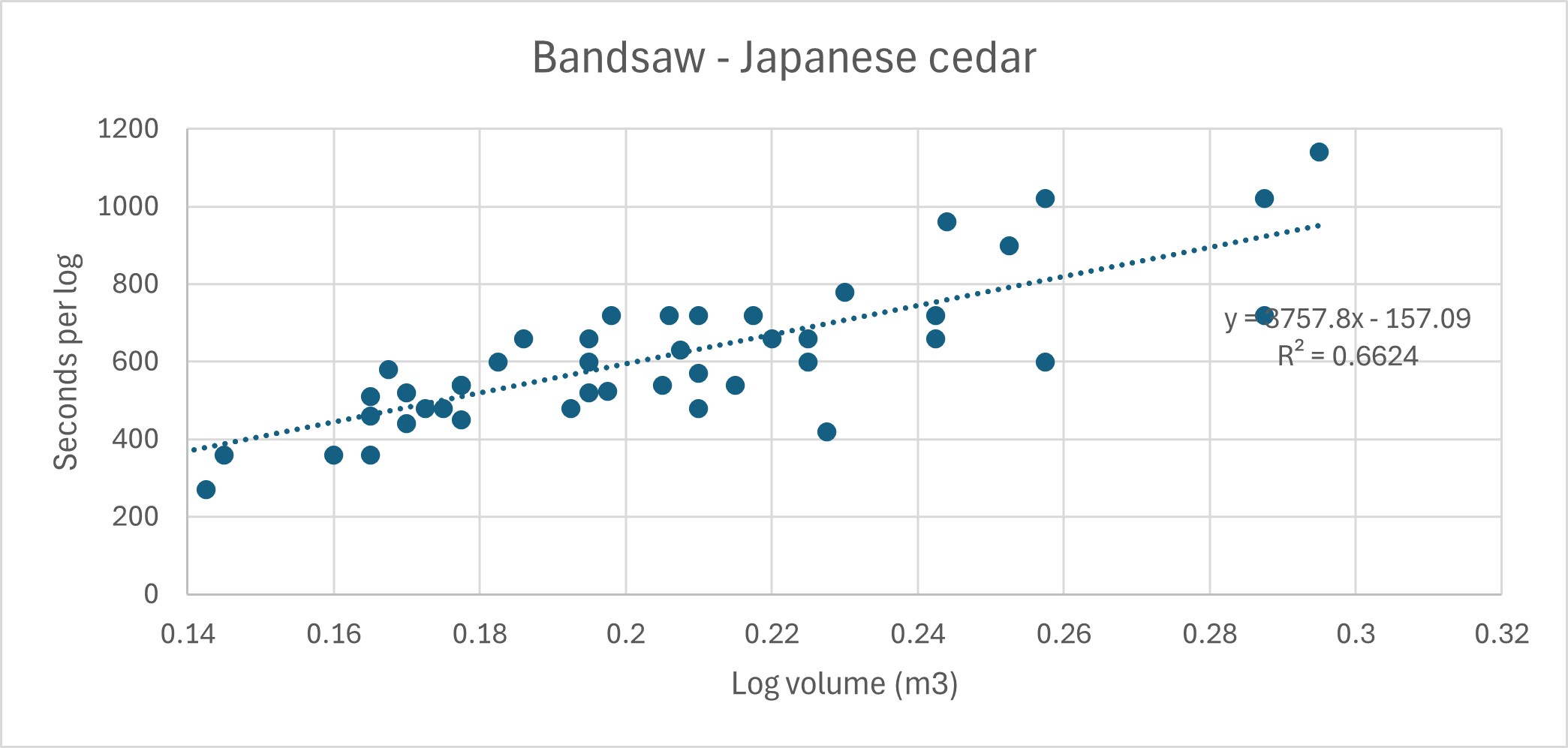

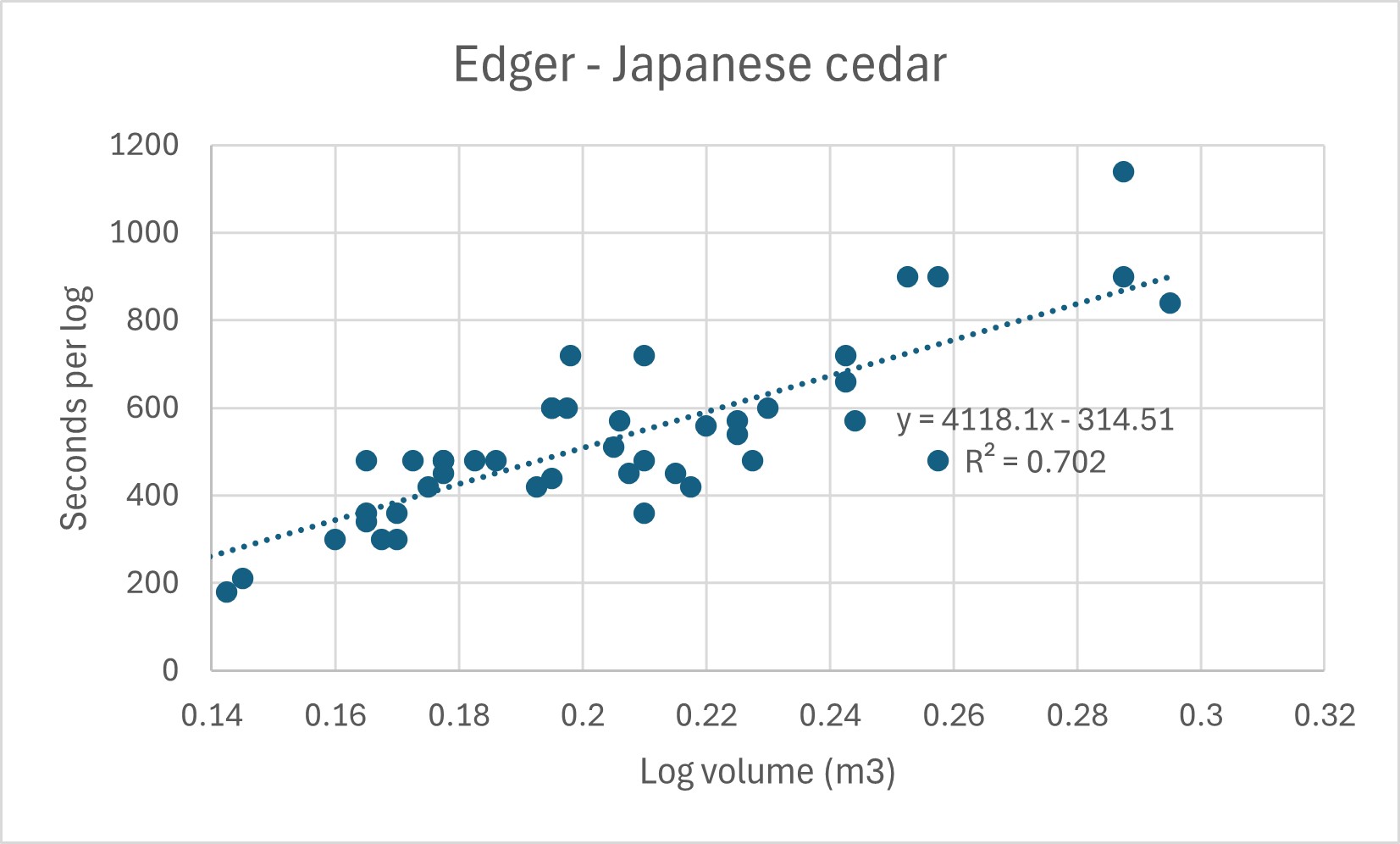

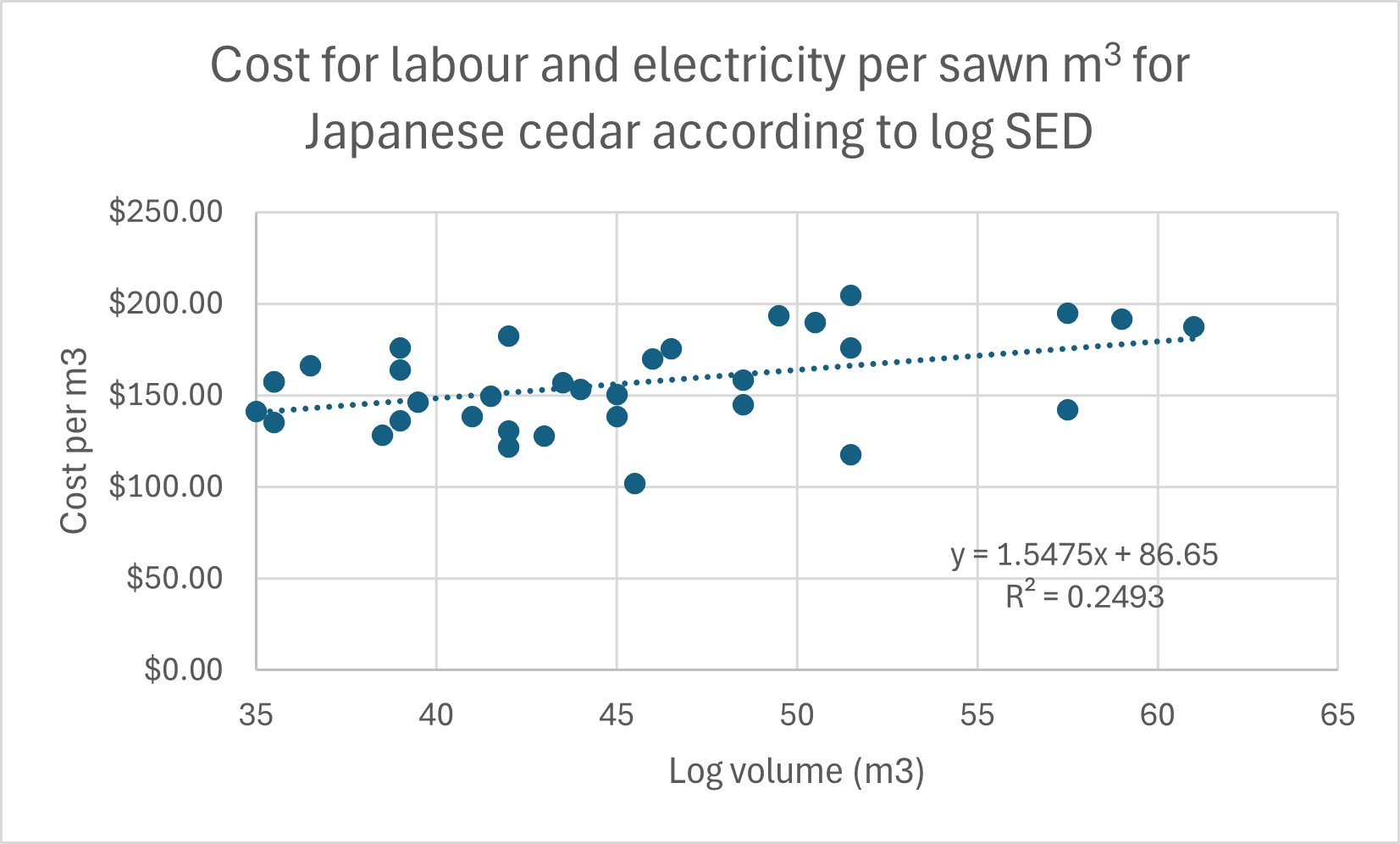

Japanese cedar

Bandsaw volume sawn vs time regression was statistically significant with a P value of 6.13E-12

Edger volume sawn vs time regression was statistically significant with a P value of 3.85E-13

Discussion

Log diameters suitable for this sawmill are between 250mm and 700mm LED. This log range matches the expected available resource, although larger logs are likely to become available in smaller quantities at times. Larger logs can be split through the middle to be presentable to this sawmill, and if these become regularly delivered, equipment suitable for splitting large logs will be required. The sawmill was designed for logs no smaller than 250mm, because these are not expected to be economic to mill into sawn products. There is scope for modification of the end dogs to take smaller logs if this proves to not be the case.

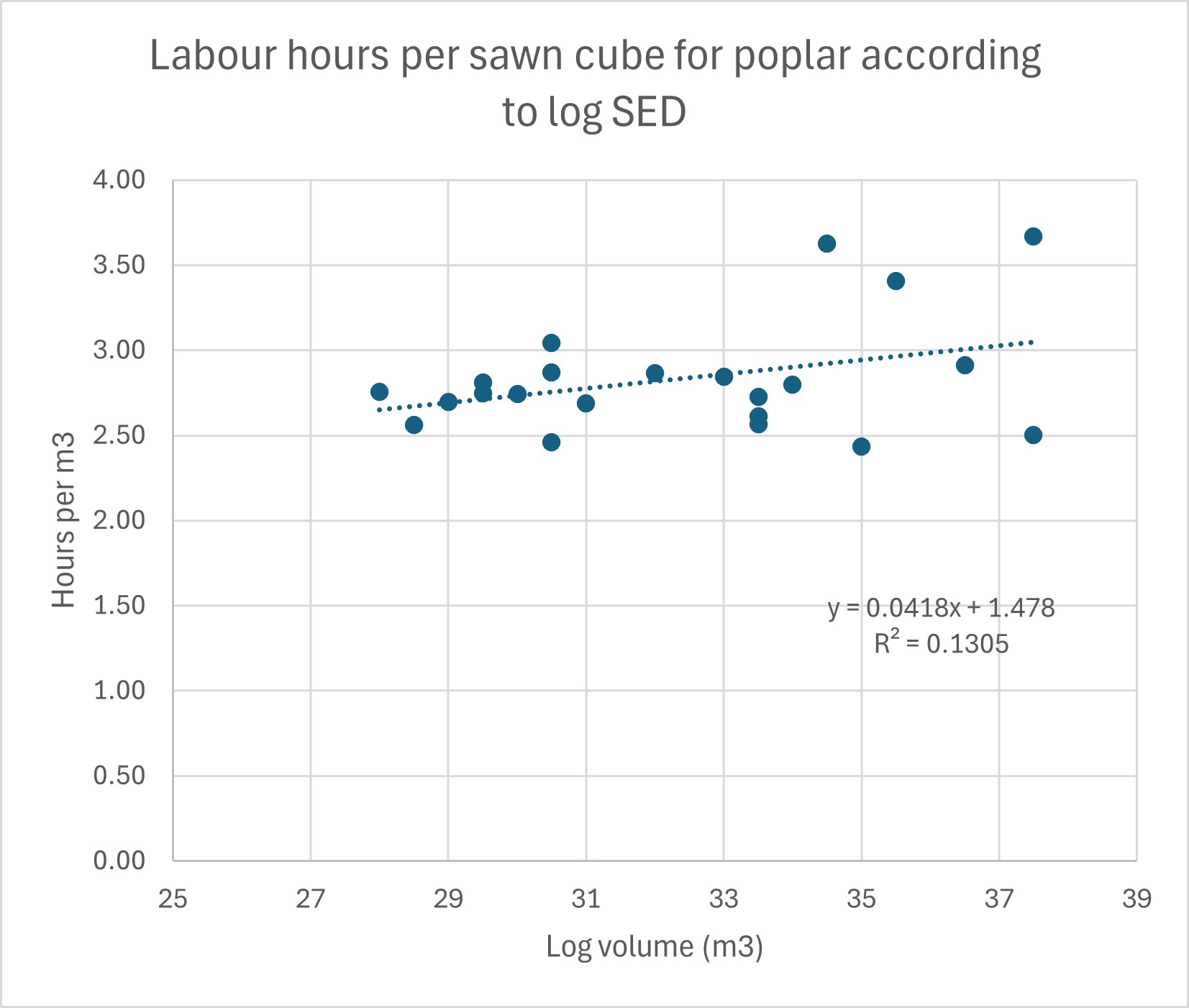

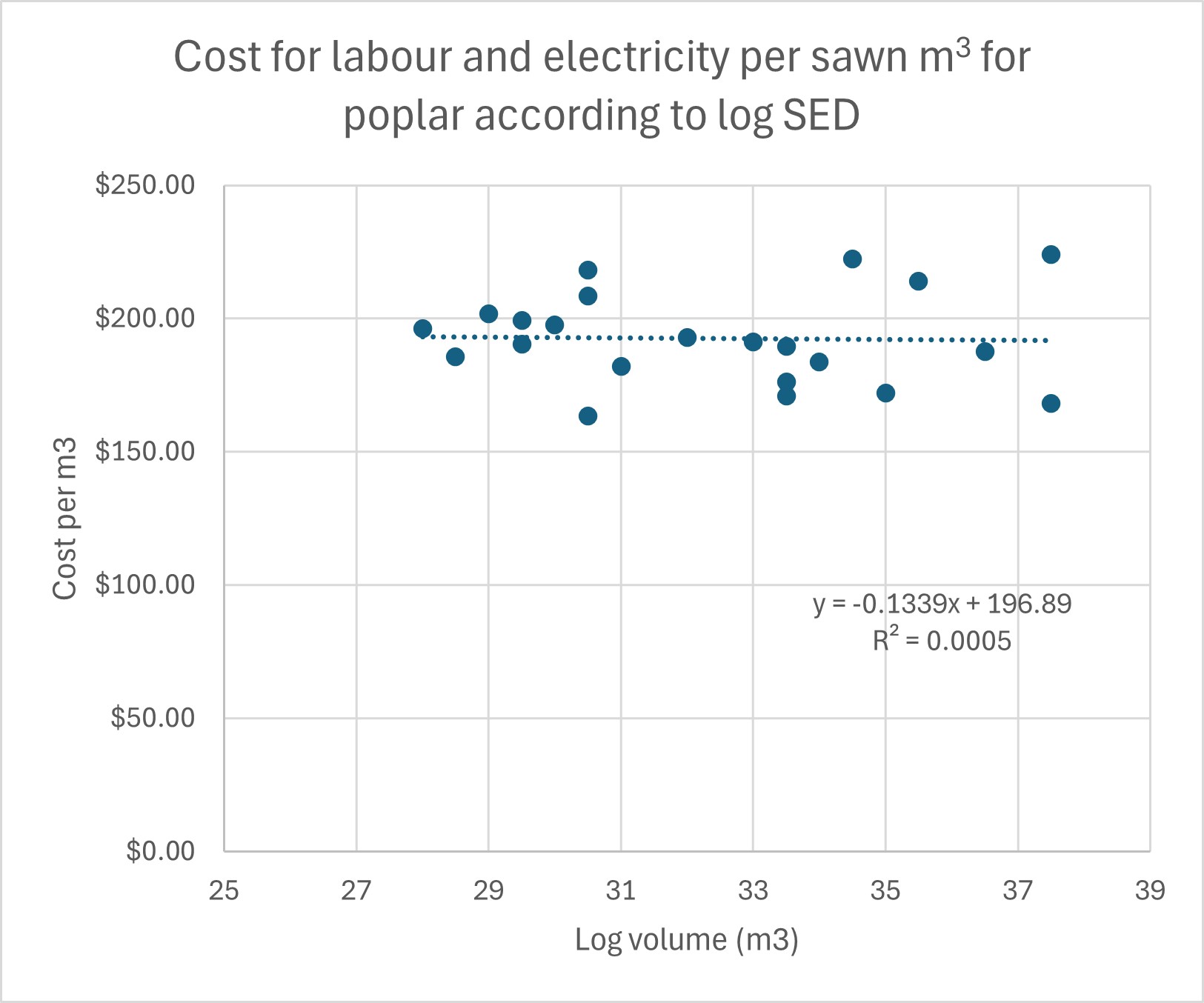

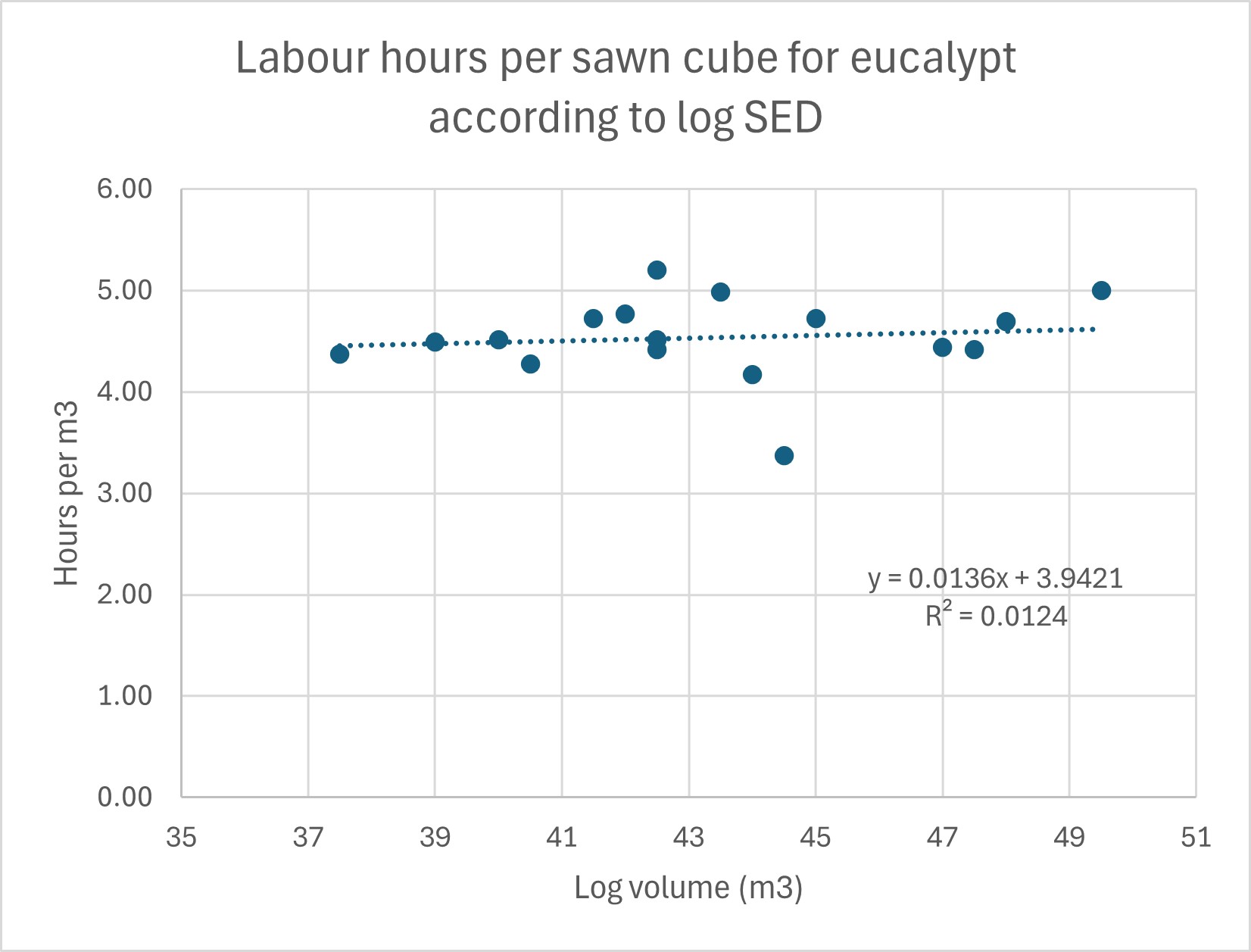

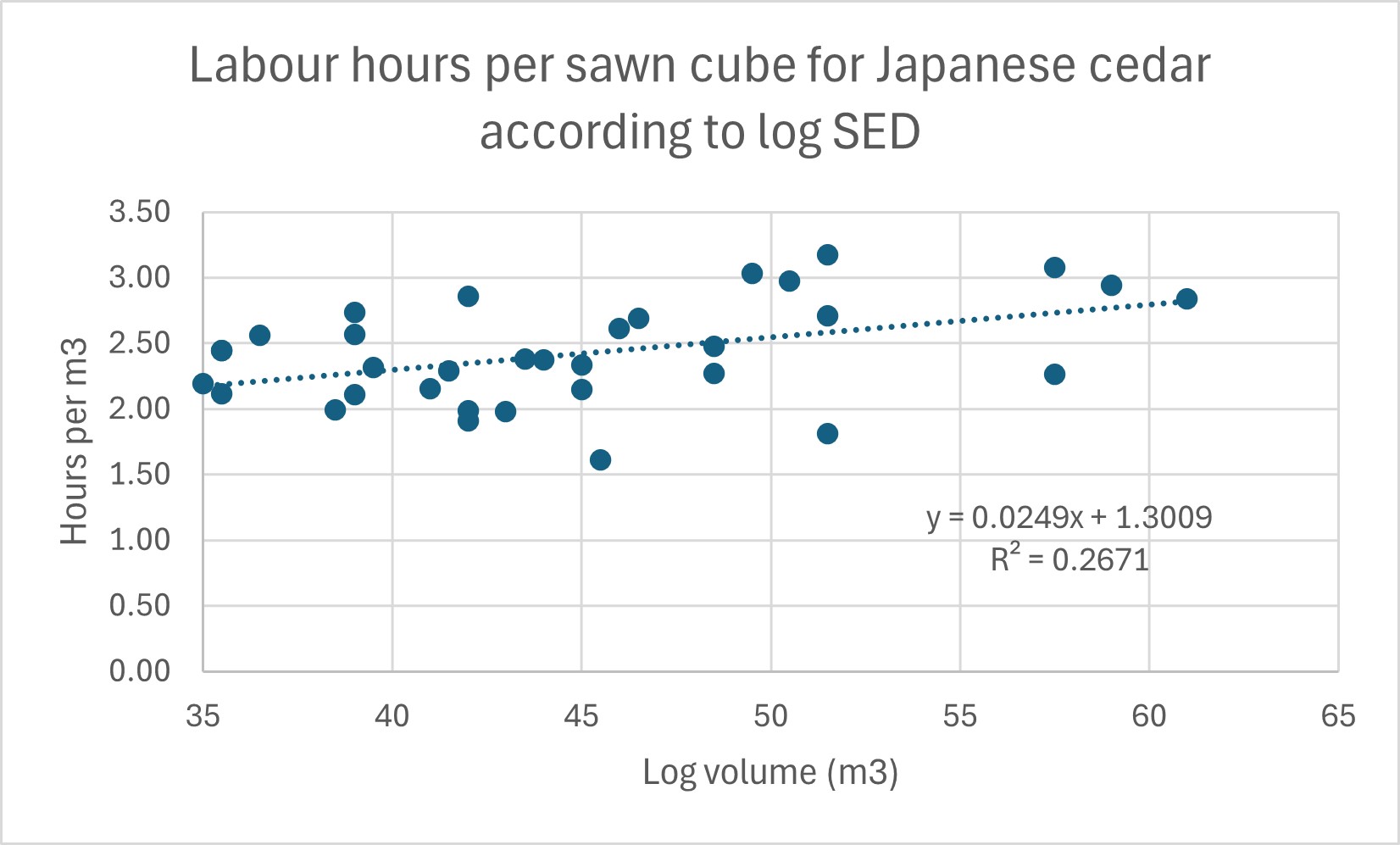

Sawmilling costs per m3 generally increased slightly as log diameters increased. This is primarily because larger slabs were more difficult to handle using the existing sawmill configuration, in particular the outfeed table requires modifications. Grade recoveries from larger logs can be expected to improve from those of smaller logs, so log diameter is not expected to influence returns once the sawmill line is improved.

The layout of the sawmill is expected to be refined over time and there is significant scope for improving production rate. A number of efficiency improvements are underway and additional issues have been identified for improvement. It is expected that length of time to saw 1 cubic metre of timber will be reduced to 3.5 labour hours for eucalypt and 1.5 labour hours for Japanese cedar, with some simple adjustments.

Comparing productivity of this sawmill with other small-scale sawmills in New Zealand suggests the productivity of this sawmill line to be favourable. John Fairweather Specialty Timbers contract mills on an hourly rate but reports that they cut a maximum of one cubic metre of sawn timber every two hours with three labour units (J. Fairweather, pers. comm, January 2026). Denis Budd (pers. comm January 2026) reported that Mid Western Sawmills cuts a maximum of 5 cubic metres of sawn eucalypt every day, using 5 labour units. Li Legler, who operated the bandsaw in this study and has experience using a Woodmizer LT40 for milling all three species, reported that "this sawmill is at least twice as fast as my Woodmizer" (pers. comm, February 2026) .

Conclusions

The prototype testing demonstrates this sawmill to be efficient, versatile and functional. Although improvements have been identified for future builds, the protoype itself has few flaws and will be used for commercial sawmilling by its owner. Taking into account the risks with building a prototype, the data is heartening. The vision remains that sawmill lines be built around New Zealand based on this design to generate sustainable regional markets for logs and sawn timber of specialty timber species. Two-hundered and fifty tonnes of logs have been purchased for milling, to further develop the techniques and technologies while testing the durability of the mill.

Specialty Timbers New Zealand

Specialty Timbers New Zealand

No posts yet

Add a post