Specialty timbers newsletter 24, April 2023

|

Farm Forestry Timbers |

|||

In this newsletter:

The key step in developing markets for specialty timbers is provision of a co-ordinated, co-operative supply chain. The Farm Forestry Timbers vision is that suppliers work together, despite being competitors, because market development is necessary and bigger than the individual. In recent times however, suppliers have enjoyed selling everything they can produce because of the building boom. Standard practice during good times is to bury ones head in the sand until the issues rear their ugly head again, when nobody has any money to deal with them. Why be part of a market development strategy when the going’s good? Well, turning a blind eye to the issues doesn’t make them go away. These issues include:

There remains little understanding of “the right wood in the right place” by the construction sector, who have not yet been challenged on business as usual, particularly construction waste, embodied carbon and end-of-life disposal. The Industry Transformation Plan (ITP) for the forest and wood processing industry highlights the need to diversify our forests and our timber products. The ITP requires an industry/government partnership to action this transformation. As the only industry body representing the interests of growers and producers of specialty timbers, I hope that Farm Forestry Timbers are a key player in that co-operative industry effort to transform our industry and economy. These issues are bigger than Farm Forestry Timbers, they are even bigger than the construction sector, although construction does need to take ownership of them. We'll see how this unfolds, but in my view the prerequisite for transformation is for New Zealand as a nation to embrace a circular economy and ditch the current linear extractive model. Dean Satchell If you have a story for this newsletter, please get in touch with Dean by email. Kawa poplar timber - properties and market opportunities Kawa poplar has been with us for over thirty years, yet although it enjoys a reputation for good wood density, strength and stiffness, these properties have not been characterised previously. Northland Regional Council, with support from the MPI Hill Country Erosion fund, have taken the first steps to assess Kawa's potential for a range of applications. The full report is available here. Structural poplar The focus of this first article is on Kawa's potential for structural appearance applications. That's things like exposed beams, rafters and maybe even glulam. The two big building code hurdles to overcome are proving the products durability and strength. Northland Kawa was tested for strength, stiffness and for boron preservative treatment to meet building code requirements, published in the NZ Journal of Forestry Science. A cabin was then constructed from Kawa poplar to demonstrate the opportunity for structural appearance applications. Here are some pics:

Stiffness and strength testing of solid timber Kawa resulted in a rating of SG10, which means it's strong. Boron diffusion to the H1.2 hazard class used for interior structural applications was achieved without difficulty. Glulam tests demonstrated a GL10 rating, again great. So are we there? Pretty close, we have demonstrated the promise Kawa poplar holds for structural applications. However, before designers and architects will specify Kawa for their next job there is still work to do.

Next, we need to test Kawa poplar from other regions to see whether it's just as strong throughout the country. We need to test larger glulam beams. We need to test shear, compression and tension strengths. Maybe even fixings. I'm hoping that these good results justify taking the next steps towards commercialising the species. Dean Satchell Abies grandis project report, January 2023 Couldn't find Page with ID=8233 Vaughan Kearns Farm Forestry Timbers AGM 2023 This will be an online meeting via Jitsi video conference. Where and when: Wednesday 3rd May, 8pm Click here to join the meeting: https://meet.jit.si/FarmForestryTimbersMeeting I've never put together flat pack furniture before, but when my daughter insisted on a tallboy from the Warehouse I drew the line with two conditions: Made in New Zealand and made from wood. The purchase was made, a mdf product with a fake oak finish and made in New Zealand. In fact it was made right here in Northland by Compac furniture, Dargaville. Fourty kilograms of radiata pine mdf and apparently the fake oak finish is made from paper rather than vinyl. What interested me was how it was to be assembled, and whether it could be made with solid hardwood timber like blackwood or eucalypt instead.

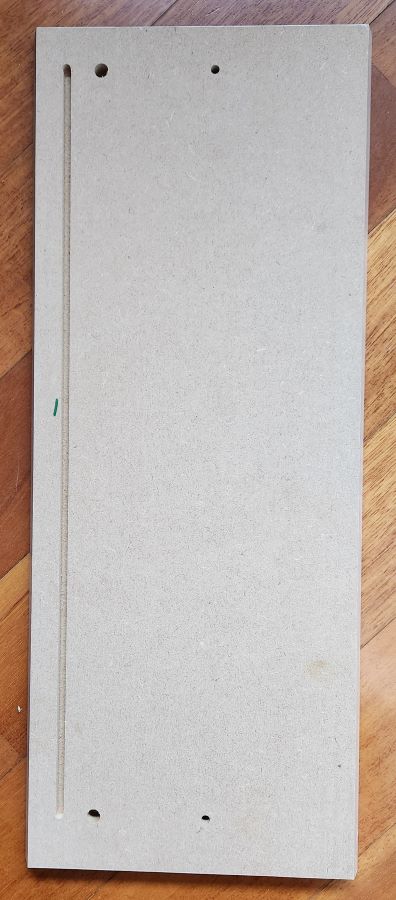

The tallboy was made entirely from lots of small pieces of rectangular mdf with holes drilled in exactly the right places. Although grooves were also routered in some of the pieces, there was no special wizardry involved.

Assembly was with screws, dowels, connecting bolts and cams.

Overall the tallboy was very easy to assemble. However, this is no family heirloom. The fake oak surface will eventually wear away exposing the mdf underneath and it won't see the next generation. I'm convinced a quality product could be produced from locally grown specialty timber. Back of my envelope the solid timber version would cost $200 more than the $420 I paid for the fake oak tallboy. I'd certainly have bought it if it were available.

|

|||

Disclaimer: While every effort is made to ensure the accuracy of the information provided on this site, Specialty Timbers New Zealand Inc. do not accept liability for any consequences arising from reliance on the information published. If readers have any doubts about acting on any articles they should seek confirming, professional advice.

Specialty Timbers New Zealand

Specialty Timbers New Zealand

Special connecting bolts and cam fittings

Special connecting bolts and cam fittings